This Lean training is tailored for service-oriented workplaces, including professional service firms, public-sector agencies, and educational institutions – organizations where much of the work takes place in offices, administrative areas, and service settings

Lean-Powered Improvement Training

This workshop delivers a solid working knowledge of Lean-powered improvement – while developing the skills, abilities, and confidence of workshop participants.

This workshop delivers a solid working knowledge of Lean-powered improvement – while developing the skills, abilities, and confidence of workshop participants.

They get an immediate opportunity to put Lean methods and tools to work. And they plan how they’ll put their know-how to work going forward – on their own and in their work groups. This is a hands-on session that gets positive change under way.

Lean Six Sigma is a body of knowledge and practice focused on understanding work in terms of processes. Lean-minded people strive to eliminate inefficiencies, ensure effectiveness, and deliver the very best to their customers. This workshop brings the concepts down to earth, supplying a set of simple yet powerful techniques for achieving real improvement right away.

Workshop formats: 1 day, 2 days, 3 days

Workshop formats: 1 day, 2 days, 3 days

Participants in the 2-day and 3-day formats receive Yellow Belt Certification upon demonstrated use of a Lean method or tool in their workplace.

Who it’s for: Depending on your needs and circumstances, the training can involve a large or small group (maximum 20, minimum 5). Sessions can be all-inclusive, with staff and managers having a shared learning experience. Or, they can be tailored for specific groups. For example, it works great when everyone (or at least several people) from a work area or team attend, because they can discuss their new know-how and plan how to use it together. This increases the chance that the ideas and tools will gain traction when the workshop winds down and people ramp back up with their regular work.

Add-on sessions: A 1-day Power Session or Deep Dive Session can be added. It’s typically scheduled for the day after the workshop.

What is a Power Session? (click to open, click again to close)

This day is facilitated by the workshop leader. It’s a great opportunity to leverage Lean approaches while the learnings are fresh in everyone’s minds.

Example: A subgroup of workshop attendees spends the day mapping their current-state work process and pinpointing waste. They identify a set of “just do it” improvements – and identify several more-involved next steps. Then they build a plan that identifies all actions to get this done over the next several weeks, with start/finish dates for each action, and clear designation of who’s leading and who else is involved.

Example: A subgroup creates a high-level process map, discusses process-related measures, gets added guidance from the workshop leader, reaches consensus on a set of several high-priority measures to follow going forward – then develops a scorecard so they can easily see and track these measures on a week-to-week basis.

What is a Deep Dive Session?

Workshop Content

Click below for a comprehensive list of topics that are covered in the workshop. Foundational topics are covered in all of the time formats, and the concepts are brought to life with hands-on activities and real-world application.

Longer sessions allow for more content, with the 3-day session covering all topics shown below.

For a given workshop, the final agenda is based on the group’s current level of know-how, the workplace culture, the near-term objectives and longer-range aspirations, and an understanding of which Lean approaches are likely to bring the greatest benefit to the workplace over the next six or so months.

Key Concepts for Lean-Powered Improvement (click to open)

Voice of the customer

Systems thinking, process perspective, flow, pull

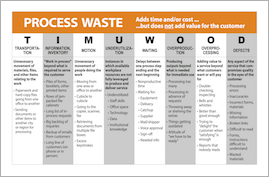

Waste, value, value added vs. non-value added

Facts, data

Variation, standardization

Prevention

Root-cause analysis

Daily Lean

• Kanban boards, personal kanbans

• Meaningful measures, visual management

• Huddles

• Rapid problem analysis

• Identifying and acting on “just do it” improvement opportunities

Structured Methods & Tools

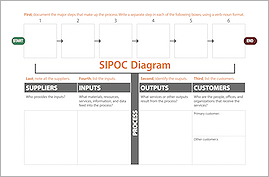

Making the invisible visible:

SIPOC, process walk, process mapping

Process waste:

TIMUWOOD (transportation, information/inventory, motion, underutilization, waiting, overproduction, overprocessing, defects), value-added vs. non-value-added

Smart problem-solving:

Using the A3 approach in order to be systematic in analyzing and solving problems (based on the plan-do-check-act cycle)

Workspace improvement:

Using the 5S method to bring order and organization to a workspace, so that employees can do their work more efficiently, effectively, and safely

Standard work:

Establishing and following a best-practice standard using templates, maps, and job aids to ensure consistency – and using it as the starting point for future improvement

Improvement Events

Setting the stage for success:

Right-sizing the scope, developing the charter, building the team, etc.

Types of improvement events:

• Kaizen events to transform key processes

• Multi-session process improvement events

• Small-scope improvement events

• Value-stream mapping (strategic, higher level)

Ensuring implementation and results:

Post-event next steps, action plans, update meetings

Meaningful Measures

• Keep an eye on process performance and capability

• Gain insights into processes

• Identify areas of the process that call for further investigation, for just-do-it improvements, or for a fuller improvement effort

• Make informed decisions

Success Factors

• Constancy of purpose

• Establishing new workplace routines and habits

• Implementation traction, persistence, flexibility

• Effecting positive change by engaging and supporting others

• Understanding and managing team dynamics, facilitating teams

• Tracking progress and results to fuel continuous improvement

• With improvement events: Event-to-implementation handoff, role of the project manager, communication, update meetings

Making sure this new know-how is used: Toward the end of the session, participants are guided in thinking about, talking through, and planning out how they’re going to put the most promising Lean-powered approaches to work. Individuals determine their own action steps. If teams or work groups are present, they decide on their collective actions. The final step engages the entire workshop group as they’re prompted to identify several doable next steps that can benefit the workplace as a whole.

For more information: Click to send a note, or call 614-571-9529.

.