You’ve come to the right place for buzzword-free info about work, workplaces, and workplace improvement. These posts are all about improving work processes, strengthening teamwork, sharpening management skills and leadership skills, improving communication, and more. This is info you can use right away, full of practical ideas in straight-talking plain English. Enjoy!

• Have a suggestion or question for a possible future post? Please let us know.

When problem solving is like pulling teeth

Thanks to a rock-hard bagel and a chipped molar, I’ve become a zealous advocate of root-cause analysis.

You’re familiar with the concept: Problem-solving works best when it starts with a deep dive to find the causes of problems, which are much different than surface-level symptoms.

Root-cause analysis is common sense, but it gets short shrift in most workplaces. When trying to solve problems, many people skip the analysis, make assumptions, and rush to solutions.

That’s what happened with my chipped molar.

My dentist took a look, judged the tooth to be okay, sanded it down at the corner, and sent me on my way.

Two weeks later it chipped again. The dentist took another look, installed a crown, and predicted a long and happy molar life.

But a month later, pain set in. This led to a root canal and pain relief, followed two months later by pressure sensitivity that was more subtle but ongoing.

That’s when the real fun began: a year-long series of trips to see my dentist (four times), an endodontist, a second endontist (second opinion), a gum specialist, and an oral surgeon.

Most were left scratching their heads, but two of these people took an activist posture right away, recommending that I have the tooth “removed” (their word).

It’s one thing to talk about root-cause analysis in the work context – and something else entirely when we’re referring to literal roots, when they’re in our jaw, and when there’s talk of yanking them out. So I was pleased beyond description when the oral surgeon took a much different approach, coming across more like Sherlock Holmes and less like the Terminator.

He was all about analysis. He took his time. He reviewed the case file in detail. He ordered up a special x-ray to get a better inside look. He ruled out an infection. He took photos of the gum, sending them to a colleague for an expert opinion.

When he called me a week later to discuss his findings, he got right to the point: “Extraction has a certain degree of finality. So let’s not rush into it unless we absolutely have to.” I couldn’t agree more.

“You report that the pressure sensitivity is moderate. My recommendation is that we take no action for about ten months. We’ll see whether the symptoms evolve, which might give us more insights. And we can get another x-ray to see if there are any visible changes below the gum line.”

Sherlock Holmes indeed! This oral surgeon was digging deep for more information to make a better decision – instead of digging deep to detach me from my precious (and possibly fine) molar.

It’s now two months later. The tooth is still with me, and the pressure sensitivity seems to be lessening. We’ll see what happens as the months unfold, but to say the least, I’m grateful for this doctor and his commitment to root-cause analysis.

The fact is, he models what we all should be doing at work.

It’s time-consuming to take a problem and examine why it’s happening – then to ask why again and again to get a deeper understanding. It’s tedious. It’s hard work. But it’s the surest way to find best-fit solutions.

Chew on that the next time you encounter a problem at work. Just be sure to avoid the rock-hard bagels.

These 7 simple questions will transform your meetings

If you’re tired of the same old slow-going meetings, crack open these 7 questions.

Ask them each time you have a meeting, keep at it for a month or two – and we guarantee your meetings will be time better spent.

What will we accomplish? State a clear intended outcome for every meeting. “Decide on…” “Create…” “Brainstorm…” “Reach agreement on…” “Determine…” “Establish a timetable for…” If you have multiple agenda items, do this for each. If there’s no tangible end in mind, show mercy for your colleagues and skip the meeting.

Why is this important? Link the intended outcome to some larger project or goal or other purpose. If there’s no real connection, then revisit the “what will we accomplish” question. You might need to refine your intended outcome – or maybe you need a couple one-on-one conversations instead of a multi-person meeting.

When will this meeting end? Set an exact time, and stick with it. If the meeting request specifies an end time, affirm it when the group convenes. This might sound like a statement of the obvious, but the truth is, too many meetings go on too long because there’s no carved-in-stone end point.

What proven practice will make this a better meeting? Pinpoint something that you or someone else did that made a past meeting more successful. Put this practice to work at the current meeting. This is the surest way to improve your meetings steadily over time.

As the meeting winds down: Did we accomplish what we set out to accomplish? Circle back to your intended outcome for an important reality check. If necessary, do some meeting triage to decide how you’ll make the most of your remaining meeting time.

What are our next steps? On a flipchart or whiteboard, list all upcoming action steps decided upon during the meeting – along with who will do what and when.

What will I be sure to do for the next meeting? Maybe it’s a “do” based on something that went well. Maybe it’s a “don’t” from something that fell flat. Either way, this question is all about getting smarter and making good use of everyone’s time going forward.

Lean on “Tim” to improve your work processes

|

If you manage or work in a process that frustrates staff and falls short of customer expectations, here’s great news: Tim can help, he can start now, and he works for free.

Who is this generous Tim?

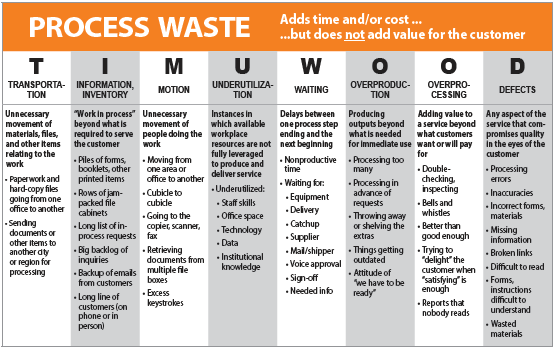

Well, he’s an acronym, designed to make a key concept more memorable. His full name is TIMUWOOD (typically referred to as Tim U. Wood). Each letter stands for a different form of process waste – a point where the process is overly complicated or too slow or redundant or error-prone.

Click on the thumbnail for a TIMUWOOD one-pager. This isn’t the only summary on the web, but it’s the best. It conveys plenty of information in concise plain English, and it’s tailored for service-oriented workplaces. If you work for any kind of service organization – a professional service firm, a government agency, an educational institutions, or anything like that – this TIMUWOOD summary will be very relevant.

The key is to put it to work, and here’s one surefire way:

Gather with colleagues who all work in the same process. Share the TIMUWOOD handout, provide a quick overview, and allow a few minutes for review. Then prompt the group to think about their process in terms of all eight TIMUWOOD factors. Ask: Which of the descriptions on the handout seem to match what we’re seeing and what our customers are experiencing?

A couple good questions will open the conversation. As people share their views, list the discoveries on a white board or flipchart. See where the group gravitates. Look for an emerging consensus around the two or three occurrences of waste that people seem to cite most.

Now, this exercise isn’t the end all, it’s a starting point. It gets everyone thinking more deeply about their process – in a way that sets the stage for improvement.

Here are additional questions to build momentum toward next steps:

• What are some “just do it” improvements we can make right away?

• With those one or two occurrences of waste that really stand out: What’s the root cause? Some snap analysis will deepen the group’s thinking.

• Is there information or data that can help us get smarter about the situation? Who can do some research and get back to the group?

• How about a process walk? Some groups get so curious from their TIMUWOOD conversation that they schedule a start-to-finish walk-through of their process – literally going from station to station so everyone can get a better understanding of what goes on. This isn’t always feasible because some processes reach beyond a given location, but when it’s doable, a process walk with a cross-functional team will yield all sorts of useful findings.

• How can we hear from the people we serve? Processes exist in order to deliver something of value to customers, so customer input is the ultimate reality check. A few questions posed to select customers will uncover important insights.

Can all this improvement really start with a single page? We’ll let Tim answer that.

![]() Download the 1-page TIMUWOOD handout (PDF 91KB)

Download the 1-page TIMUWOOD handout (PDF 91KB)

Here’s how 7 words (or less) can thrill your customers

Quick, can you convey your mission in seven words or less?

How about your #1 work-related goal – can you rattle it off in a quick phrase?

Most of us can’t, but Mukesh Thaker certainly can.

Most of us can’t, but Mukesh Thaker certainly can.

He provides IT support in a big organization – the kind of organization where mission statements and goals can be wordy and remote.

Mukesh operates with his own down-to-earth mission, which he’ll tell anyone who asks: “My goal is to make people happy.”

Critics might say it’s too touchy-feely or too pie in the sky. Others might say it’s too vague and inherently unmeasurable.

But for Mukesh and his customers, “happy” is what matters most. He visits with people when they’re having problems with their computers, or connections, or software, or a combination of the above. When Mukesh solves problems, he makes his customers happy. He hears it in their words (thank you) and sees it on their faces (smile). Goal achieved.

We can all take a page from the Mukesh playbook.

Start by phrasing your mission in seven (or fewer) meaningful words. Enshrine your words on a sticky note. Keep it front and center for a full work week. Revisit at week’s end. Fine-tune as needed. Keep it visible until it becomes second nature.

And what if you can’t come up with a suitable phrase that informs and inspires?

Easy. Take the “make people happy” mantra and make it your own. Turn it into your daily imperative.

Mukesh will be thrilled, and so will the people you serve.

The power of “I really don’t care what people think”

Would you adopt a new approach if it promised improved performance and better results? Sure you would.

But what if that sure-fire approach was, well, unorthodox? What if it prompted eye-rolling among colleagues? What if it made you the occasional butt of jokes? Would you adopt it then, or would you stick with your old approach to avoid the grief?

For Rick Barry, it was an easy choice. During his 14 seasons as a professional basketball player, he threw all his free throws underhanded – while his court colleagues used the standard overhand toss.

Did Barry’s underhand throws look silly? Who cares if they did – they produced so many points that they became a big-time competitive advantage.

Barry sank 90% of his free-throws – compared to a 75% average for everyone else. In his last pro season (1979-80), he took top free-throw honors with an average of 93.5%.

The Hall of Fame forward scored 25,279 points during his career. Named to 12 All-Star teams, he led the Golden State Warriors to the NBA Championship in 1975, averaging 30.6 points per game in the 4-0 series – and earning MVP honors. Did free throws matter? Two of those games were won by one point.

Among today’s basketball players, Chinanu Onuaku is following Barry’s lead. In his freshman year at Louisville, Onuaku made just 47% of his free throws. He adopted the underhand approach, put in the training time, and upped his average to 59% in his second year.

Now with the Houston Rockets, Onuaku is still tossing his free throws the unorthodox way. His comment to Sports Illustrated says it all: “I really don’t care what people think. As long as I get a bucket, I’m fine.”

It’s true in any setting where performance is important. If you don’t care what people think, you’ll find all sorts of new approaches that can score better results.

Have you found a unique scheduling system that goes against the grain but gets great results? Stick with it. Are you getting new insights from customers by organizing a first-ever series of focus groups – while getting curious looks from colleagues? Stay the course. Are you gearing up to bring process mapping to your team, knowing that it works but also knowing that some team members will balk? Trust your know-how and go for it.

MVP status awaits.